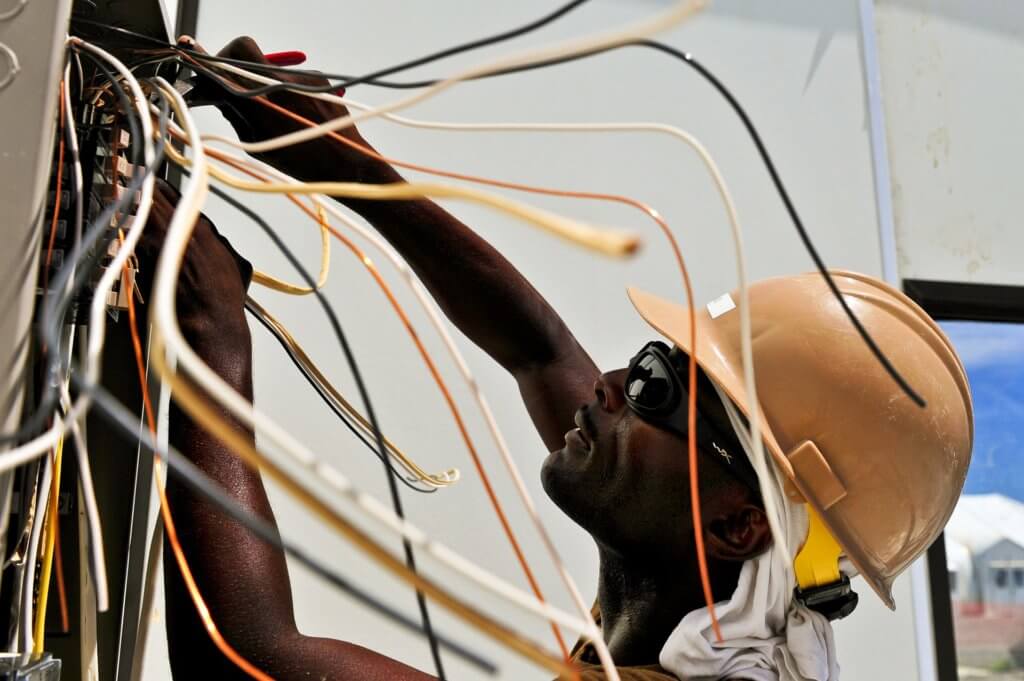

It’s a risk that electrical workers face every day on the job: Arc flashes occurring without warning and causing an injury that can be severe. The most serious of these burn injuries typically happen when clothing ignites and continues to burn, so it stands to reason that the right apparel – arc-rated (AR) and flame-resistant (FR) – can offer protection from these painful burns.

What Causes Arc Flashes?

- Electrical worker error: Occasionally, workers fail to verify that there is no voltage. They might be using faulty voltage testers or forget about lockout/tag-out procedures. Overconfidence, complacency, and poor communication can all contribute to arc flashes.

- Working on energized equipment: There are situations in which workers must work on hot equipment—hospitals are a perfect example. But there are times when workers believe they have the experience to work on energized equipment or they don’t de-energize because they are pressed for time.

- Lack of equipment maintenance: When equipment is not regularly maintained, corrosion can build up and increase resistance and heat. Corrosion is one of the leading causes of equipment failure and arc flashes.

Electrical Workers Can Protect Themselves with Flame-Resistant Wear

Electrical workers are usually not burned severely by the arc flash itself. Instead, the significant injury occurs when non-FR clothing ignites and fuels the flame. The extent of the injury is increased with the worker experiencing severe and painful burns.

Flame-resistant apparel will self-extinguish, which lessens the burn injury since the source of ignition is removed. It also provides enough insulation to reduce the likelihood of second-degree burns significantly.

FR Daily-Wear is a Simple and Effective Solution

For the most common lower-energy work, wearing AR/FR daily-wear could be the solution. It takes away the guesswork of deciding whether a task requires arc-rated clothing, and it eliminates that extra step of getting into personal protective equipment (PPE) for a specific job. For high-energy tasks, however, the extra step of donning appropriate task-based PPE is recommended or required.

Match Your Clothing to the Hazard Levels

The National Electrical Safety Code (NESC) requires utilities to assess the hazards for employees working around energized equipment. If energy exceeds a certain level, workers must wear AR/FR clothing with an arc rating equal to or higher than the levels with which they work.

Employers may be required to perform an arc-flash risk assessment to determine the potential energy level and the total area in which the hazard exists. Once the energy level and total area are determined, you can select the appropriate AR/FR clothing. Start by choosing a fabric that gives you the comfort and performance that meet the needs of your workplace and the tasks you’ll be performing.

Are You Looking to Advance Your Career as an Electrician? Contact Outsource!

Let us help you. Find your next job at Outsource. We are the largest staffing firm in the nation specializing in the placement of low voltage and electrical talent.

Discover The Power of Real Partnership

Let's talk about the world of possibilities and how we can partner to make them a reality.

Our Latest Resources

What's new in the world of work? Check out the latest highlights, including staffing trends, top insights and more.

Be Ready to Answer These Questions at Your Next Job Interview

Whether this is your first job interview or you've done several already, you will probably find yourself with a case of nerves as it begins...

Maneuvering Your Job Search Through a Pandemic

A global pandemic means times are uncertain, stressful and even a bit frightening. While the COVID-19 outbreak has not only caused a health crisis it has also caused an economic crisis as well...